The global fleet spends millions of dollars on fuel every day—and releases millions of tons of carbon dioxide into the atmosphere. But what if vessels could literally glide on the water’s surface, as if on an invisible air carpet? This is the ambitious idea behind Armada Technologies, a Liverpool-based company that wants to change the game in maritime transport. How they are doing it, why their invention is already being called the “anticompressor revolution,” and who is ready to install it on their ships—answers can be found on the liverpool-future.com website.

Armada Technologies: Liverpool Roots and Global Ambitions

Armada Technologies is a Liverpool company that announced serious ambitions from its very first steps. Founded in 2020, it didn’t emerge out of nowhere but in a city with a powerful maritime history. This is where fleets were traditionally formed, ships were repaired, and complex port logistics tasks were solved. And this is where the idea was born that innovation in the marine industry could start not in the headquarters of large shipping giants, but in a small office with a few engineers and a clear goal.

The founding team is united by practical experience and deep roots in the industry. Roger Armson, for example, has long managed fleets and passenger lines, while his partner, Alex Routledge, grew up in a family where port logistics was not just a business but a part of life. Routledge has the maritime theme literally in his blood: his grandfather worked at Routledge Brothers in the interwar years, his father maintained port infrastructure, and Alex himself chose a technical path and took on the modernisation of what others considered an “inert” industry.

For him, Armada is more of a challenge than a business. His vision is simple: shipping is capable of changing, but it is forced to do so cautiously. That is why technological solutions must be both progressive and realistic to implement.

“Increasing efficiency is the reform,”

says Routledge, commenting on the company’s strategy. There’s no need to invent radical scenarios if you can improve what already exists. This is the essence of Armada Technologies.

To date, the company has repeatedly appeared in the news as a promising player in marine innovation. Its main development—a system for reducing water resistance—has attracted the attention of shipowners, investors, and environmental consultants. It looks simple, yet it opens up complex possibilities. Armada is not exactly offering something revolutionary. Rather, the firm works with what really matters: fuel efficiency, ecology, and practicality in daily operation.

The “Air Carpet”: How the Passive Air Lubrication System Works

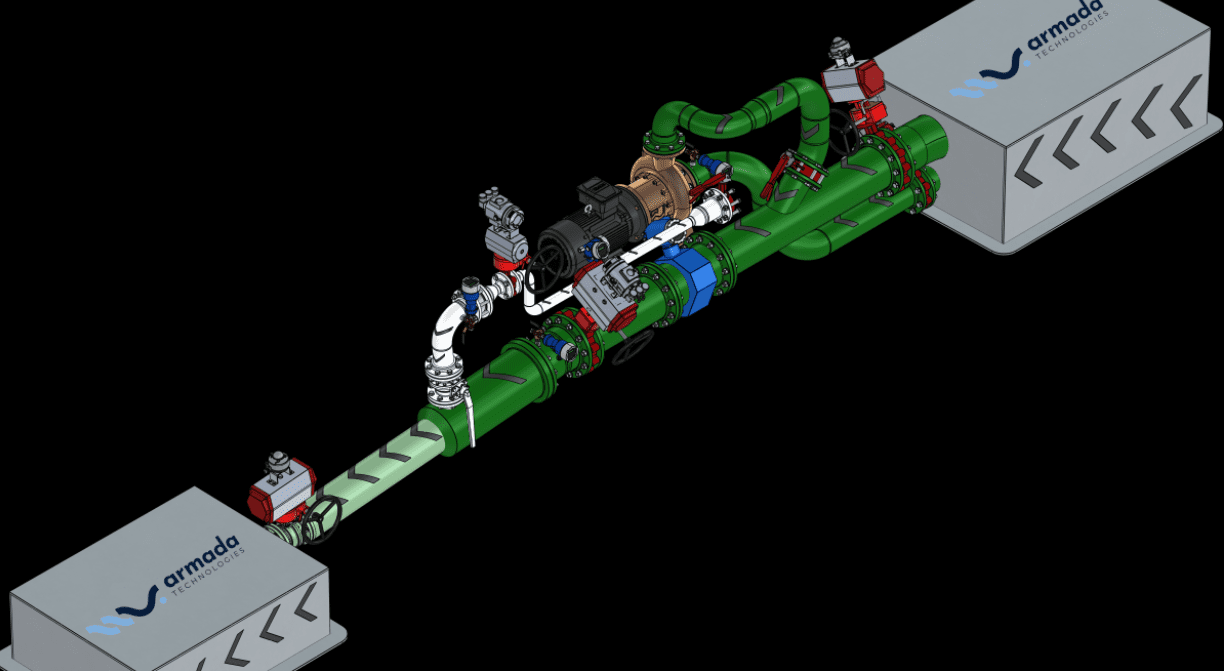

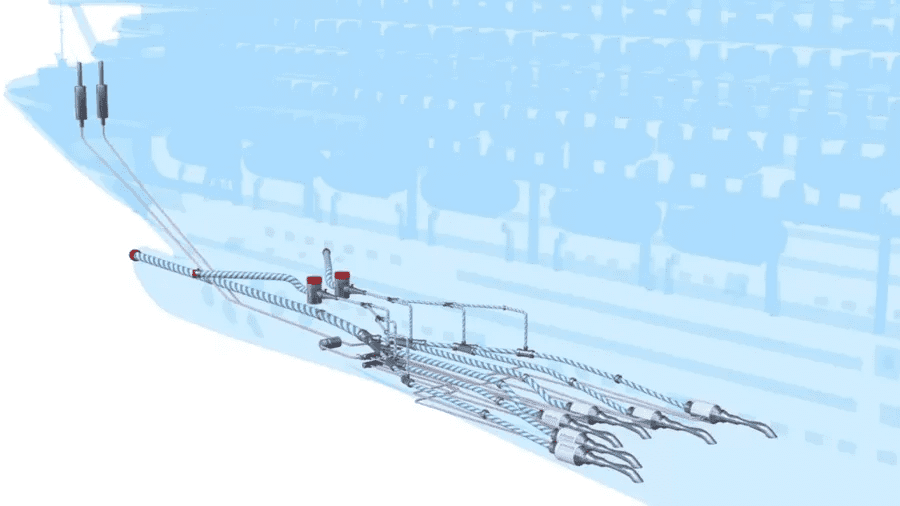

Imagine a vessel gliding on the water’s surface as if on a thin cushion of air. Does it sound like science fiction? But such bold ideas are what shape the Liverpool of the future. Armada Technologies has made this a reality, and without compressors, unnecessary equipment, or energy consumption. The invention, the Passive Air Lubrication System (or simply PALS), uses the effect of microbubbles that create a layer between the ship’s hull and the water. Thanks to special holes and a venturi system, air is naturally drawn into the water flow under the ship’s bottom, reducing friction and, consequently, fuel consumption.

Unlike traditional air lubrication systems, which require powerful compressors, pipelines, and constant maintenance, PALS works passively. The movement of the vessel itself causes air to be drawn into the water, meaning the system is activated by physics, not energy. The absence of moving parts significantly simplifies its maintenance, reduces vibrations and noise, and increases reliability. This is a true conceptual advantage: Armada changes the approach to vessel design, making efficiency natural rather than forced.

Everything about this solution looks paradoxically simple. No pumps, so less electricity. No complex systems, so fewer failures. But behind this simplicity lies deep engineering work, from flow modeling to the use of machine learning algorithms that control air distribution depending on speed, load, and weather conditions. And it is this balance between minimalism and high technology that makes the “air carpet” from Armada Technologies a truly innovative solution for the maritime industry.

Savings, Ecology, and Efficiency: Benefits for Shipowners

In an era where every gram of fuel and every ton of emissions counts, PALS technology from Armada Technologies has arrived at the right time. Tests have shown that by reducing hydrodynamic drag, vessels can save up to 10% on fuel, and therefore on costs. A definite win! But it is also a step towards fulfilling increasingly strict environmental regulations. After all, along with fuel consumption, CO₂ emissions and air pollution are also reduced, which makes the technology relevant for companies aiming to comply with IMO and ESG standards.

Another significant advantage is the simplicity of integration. The system can be installed on new vessels as well as retrofitted on existing ones. This gives shipowners a certain flexibility: they don’t have to wait for a new fleet to be built to implement innovations. Additionally, the absence of compressors means less technical maintenance, reduced noise and vibration, and less load on the ship’s power system. In the long run, this translates into lower costs and greater reliability.

For many operators, this sounds like the perfect formula: reduce costs without a major overhaul of the fleet. But efficiency is not the only argument. PALS is also barely noticeable to passengers or crew because it works in the “shadows”—silently, reliably, and almost invisibly. Ultimately, Armada is creating a new norm for the shipping industry. And the more companies that realise this, the faster the air carpet will cease to be an exception and become a standard.

Who is Already on Board: Armada Technologies’ First Partners and Big Deals

When an innovation truly works, it gets noticed quickly. Armada Technologies has already engaged several serious players, and the list of partners is growing rapidly. One of the first was the operator CoolCo, which specialises in liquefied natural gas (LNG) transport. Their vessel became the first in a series of pilot retrofits with PALS implementation, and the test results are to be published in accordance with international ISO/ITTC standards. Another high-profile case is the collaboration with Irish Ferries, who have commissioned a study on the possibility of integrating the system onto their ferry W.B. Yeats.

The geography of the projects is also impressive. Armada has signed memorandums of cooperation with Qatar Shipyard Technology Solutions and Gibdock (Oman), expanding its presence in the Middle East—one of the most active regions in maritime logistics. Such partnerships pave the way for the technology to be established as a standard in ship repair yards. All this indicates that Armada is introducing its invention to the global market systematically and confidently.

To keep up with demand, the company has already raised over $3 million in seed funding. The money went not to offices or advertising, but to development, testing, and scaling. This is how Armada demonstrates the seriousness of its intentions: this is not a technology “for later,” but a solution that is already being installed on real ships today. And if the “air carpet” indeed shows the promised figures, it’s possible that a small Liverpool team will become the driving force behind a major transformation in the maritime industry.

By the way, speaking of innovation in Liverpool: it’s not the first time the city has surprised the world with original ideas. Just think of the annual Lightnight festival, where culture, art, and technology combine in a vibrant performance.